A ceiling fan rotating at constant speed is in equilibrium as net torque acting on it is zero. How is it zero? - Quora

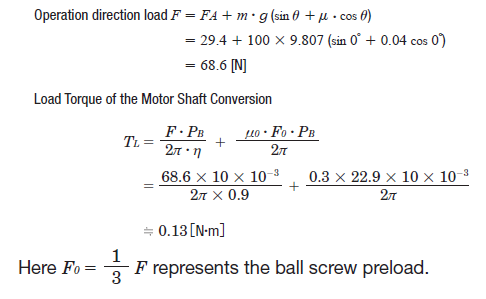

Further Information of Frequency Inverters Technical Guide for Frequency Inverters | Omron by Kyoto engineering & Automation

If a fan load is connected to a DC series motor, what are the speed, current, speed, and torque characteristics? - Quora

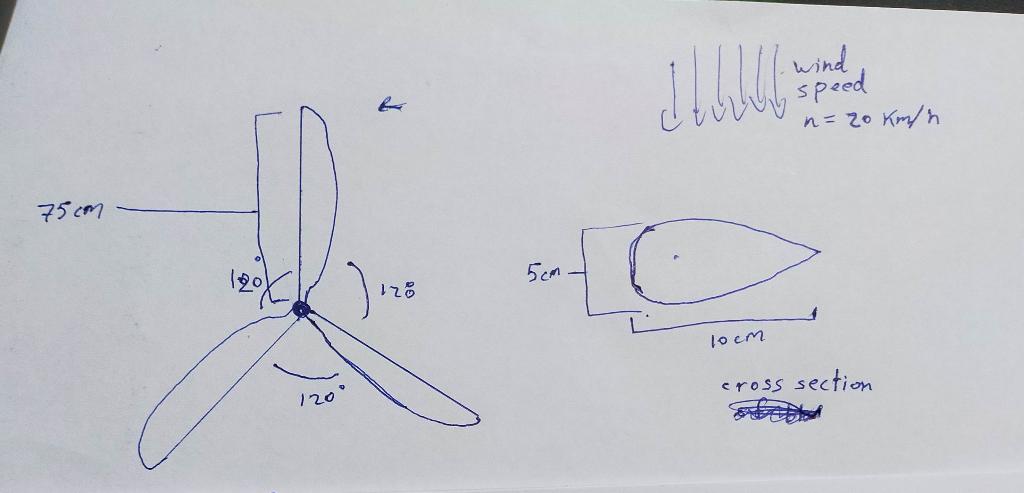

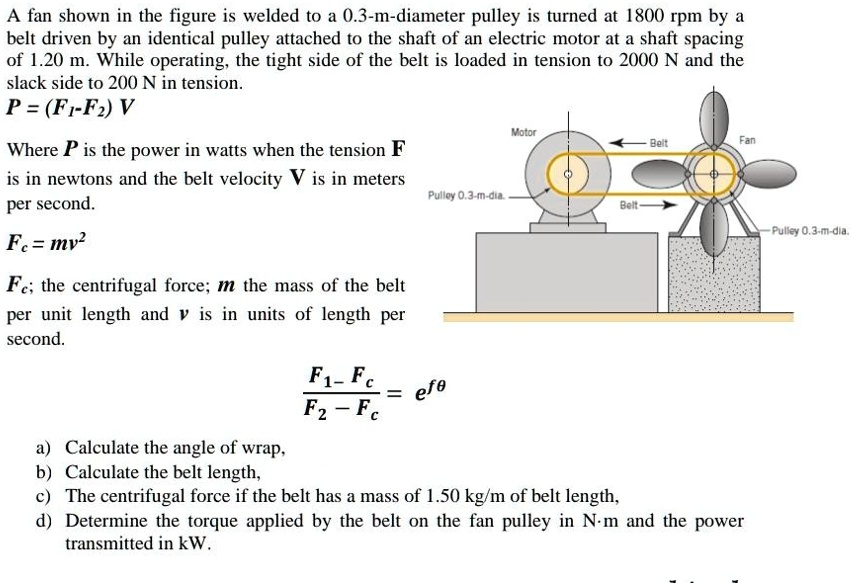

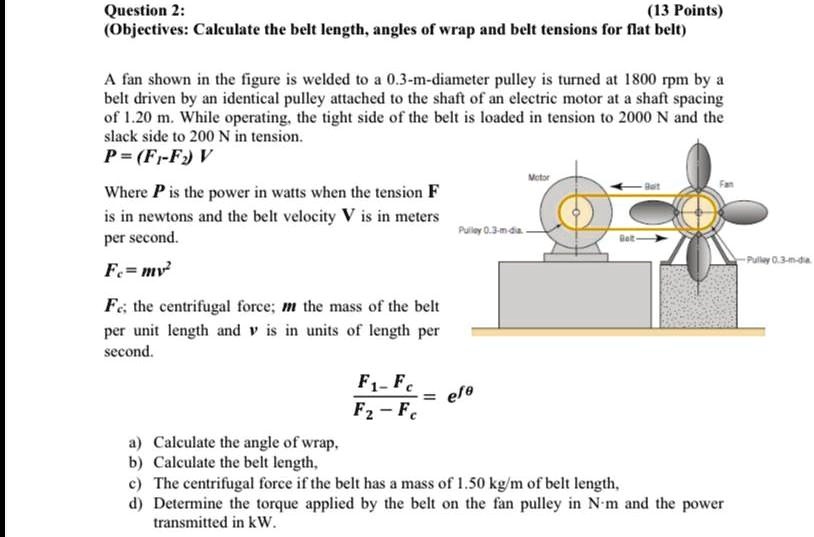

SOLVED: A fan shown in the figure is welded to a 0.3-m-diameter pulley is turned at 1800 rpm by a belt driven by an identical pulley attached to the shaft of an

SOLVED: A ceiling fan has a moment of inertia of 0.200 kg.m? When it is turned on, the electric motor applies a constant torque of 0.700 Nm to it Calculate the angular

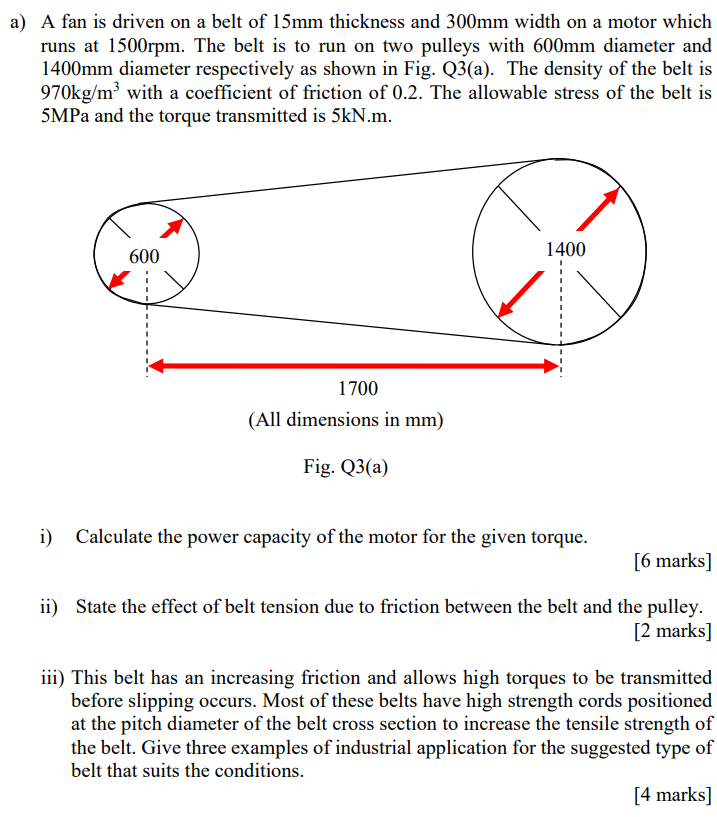

SOLVED: Machine Design and Components Question 2: 13 Points) (Objectives: Calculate the belt length, angles of wrap, and belt tensions for a flat belt) A fan shown in the figure is welded

arduino - Calculating the value of the resistance for controlling the speed of an AC fan - Electrical Engineering Stack Exchange

Applied Sciences | Free Full-Text | Digital Induction Motor Model Based on the Finite Element Method